Industrial electrical solutions for reliability and uptime

Thomas Gallant Jr Electrician Inc offers specialized industrial electrician services across Westport and the surrounding region, including switch gear maintenance, three-phase motor installations, VFD setup, transformer work, high-voltage troubleshooting, preventative maintenance, and safety inspections. Our team understands the requirements of industrial environments and provides robust electrical work that supports continuous operations and safety compliance.

Why industrial electrical services matter

Industrial facilities run heavy equipment and machinery that demand stable, well-maintained electrical systems. Failures can halt production, cause safety incidents, and lead to significant financial losses. Industrial electricians ensure systems are engineered, installed, and maintained to support continuous loads, meet NFPA and OSHA safety standards, and reduce the risk of catastrophic equipment failure or arc-flash incidents.

Key industrial benefits

Reduced downtime

Proper maintenance and rapid troubleshooting keep production lines moving.

Enhanced safety

Correctly installed switch gear and motor protection reduce arc-flash and other hazards.

Regulatory compliance

Work performed in line with NFPA 70E, OSHA, and local codes.

Equipment longevity

Well-maintained electrical systems extend the life of motors, transformers, and control equipment.

Predictable costs

Preventative maintenance reduces unexpected repair expenses and production losses.

Our industrial services in detail

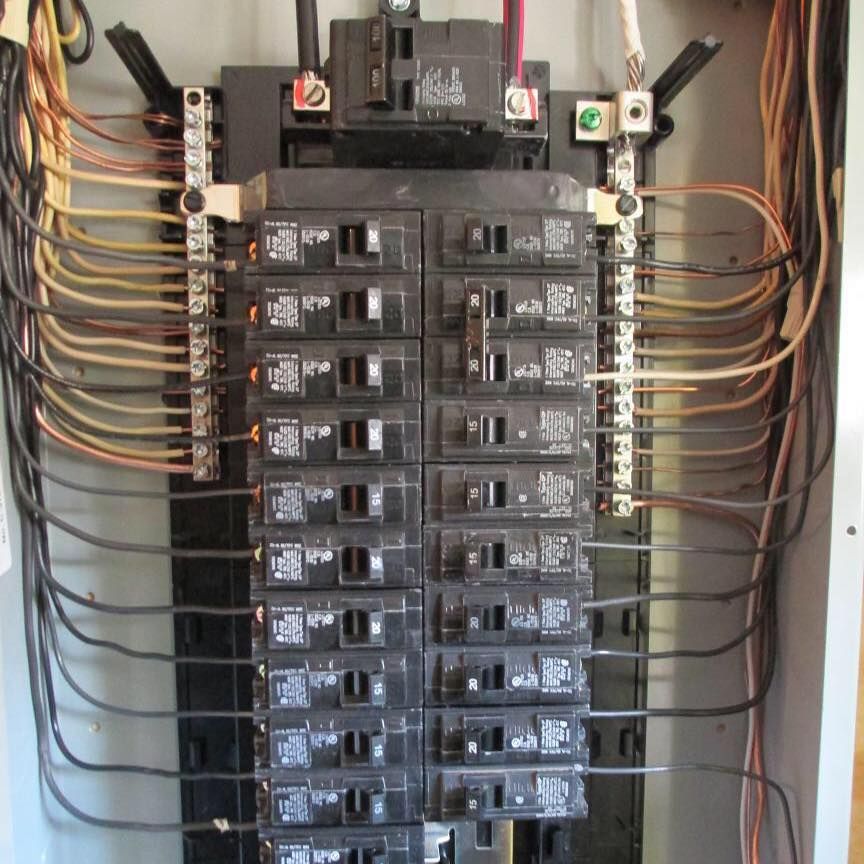

Switch gear installation & maintenance

Switch gear is the backbone of industrial distribution. We install, maintain, and repair switch gear assemblies, ensure proper coordination of breakers and protection, and perform testing to identify potential failures before they cause outages.

Three-phase motor and VFD services

We install and service three-phase motors, motor starters, and variable frequency drives (VFDs) that control speed and torque. Proper VFD installation includes harmonic mitigation, cooling considerations, and protective devices to ensure reliable performance.

Transformer installation & maintenance

Transformers must be sized and installed correctly to support industrial loads. We handle transformer replacements, secondary distribution, grounding, and oil-filled transformer maintenance procedures as required.

High-voltage troubleshooting

High-voltage systems require specialized testing and safety procedures. Our team performs diagnostic testing, insulation resistance testing, and root-cause analysis for intermittent faults or ground faults.

Preventative maintenance & thermal imaging

Scheduled maintenance programs include infrared scanning to detect hot spots in panels and connections, preventing failures due to loose connections or overloaded conductors.

Control panel wiring & PLC support

We wire control panels, connect PLC systems, and coordinate with automation vendors to ensure control systems receive proper power and protection.

Arc-flash risk assessment coordination

We work with safety planners to implement arc-flash mitigation measures, label equipment for hazard levels, and recommend PPE and approach boundaries.

Safety inspections & compliance documentation

Industrial facilities benefit from regular electrical safety inspections, equipment testing, and documentation to support audits and insurance requirements.

Emergency industrial support

Unplanned downtime is costly. We offer rapid response for production-critical faults, temporary power solutions, and expedited repairs to return systems to operation quickly.

How we serve industrial clients

Initial site review

Evaluate electrical distribution, load profiles, and critical equipment.

Tailored maintenance plans

Create schedules for thermal imaging, motor testing, and switch gear maintenance.

Qualified technicians

Skilled in high-voltage protocols, safety procedures, and industrial wiring practices.

Clear documentation

Service reports, corrective action plans, and maintenance logs for client records.

Common industrial challenges we resolve

Unbalanced loads causing motor overheating — resolved by load reconfiguration and phase balancing.

Frequent tripping of protective devices — corrected through coordination studies and protective recalibration.

Aging switch gear with poor connection points — identified during infrared inspections and repaired proactively.

Control system downtime — resolved through accurate wiring, surge protection, and coordination with automation teams.

Safety protocol and training

Industrial work demands strict safety controls. Our electricians follow NFPA 70E-compliant procedures, use appropriate PPE, and employ Lockout/Tagout practices during service. We coordinate closely with facility safety managers to maintain safe operations during maintenance or repair activities.

Frequently asked questions

Do you perform thermal imaging?

Yes. Infrared scanning is a core part of our preventative maintenance service to find hot spots before they fail.

Can you work on high-voltage equipment?

Yes. Our technicians are trained in high-voltage safety procedures and perform diagnostics and repairs with the proper safety protocols.

Do you provide emergency industrial service?

Yes. We prioritize production-critical issues and provide rapid response and temporary solutions where needed.

Contact & next steps

Protect production and reduce downtime with professional industrial electrical services. Call Thomas Gallant Jr Electrician Inc at +1 (508) 496-3319 to schedule a facility assessment or emergency service. We provide maintenance programs and rapid troubleshooting to keep operations running.